Just

imagine you’re whipping through the warehouse on your forklift, everything’s

going great, and you’re getting things done! Then all of a sudden…eeek, you’re

forced to make an emergency stop, and your forklift slowly starts tilting to the

side, your mind starts racing…what do you do?! Forklifts are massive pieces of

machinery, they generally weigh anywhere between 5,000-9,000 pounds! While

knowing how to properly and cautiously drive a forklift can help to prevent

accidents forklifts also come equipped with some safety features that can help

you along the way!

How

Much Do You Know?

a. True

b. False

2. About

how many forklift accidents occur each year?

a. 10,000

b. 50,000

c. 100,000

3. The

________ is/are an underrated safety feature.

a. Brakes

b. Horn

c. Headlights

4. Do

forklifts come equipped with seat belts?

a. Yes

b. No

c. Sometimes

Get

This…

It’s no mystery that forklifts are massive pieces of

machinery. Due to their weight and structure forklifts are prone to overturning

and tipping over; this is the leading cause of death in involving forklifts.

Because of this it is incredibly important to take proper safety precautions. Many

forklift operators attempt to jump when their forklift is tipping over. This is

never a good idea. More often than not people will get trapped under forklifts

when trying to jump. Operators should remain seated in the event of a turnover.

Although many operators prefer not to wear a seat belt this is an instance where

the use of a seat belt would be beneficial and even lifesaving!

Can

You Answer This Question???

In the event that an item falls on the overhead guard

of your forklift you should…

A. Jump

from the forklift

B. Remain

seated

If an overhead load is to fall on your forklift it is

always a good idea to remain seated in the forklift (B). Overhead guards are

put in place specifically to protect forklift operators from falling objects.

However, overhead guards are not necessarily built to withstand the fall of a

full capacity load. Because of this they are designed to “crush and deflect,”

meaning that if the impact of a load is too heavy the leg of the overhead guard

that experiences the biggest impact will crush and deflect the load to the side

of the forklift. This is why it is important to remain seated in the event of

falling objects.

Get

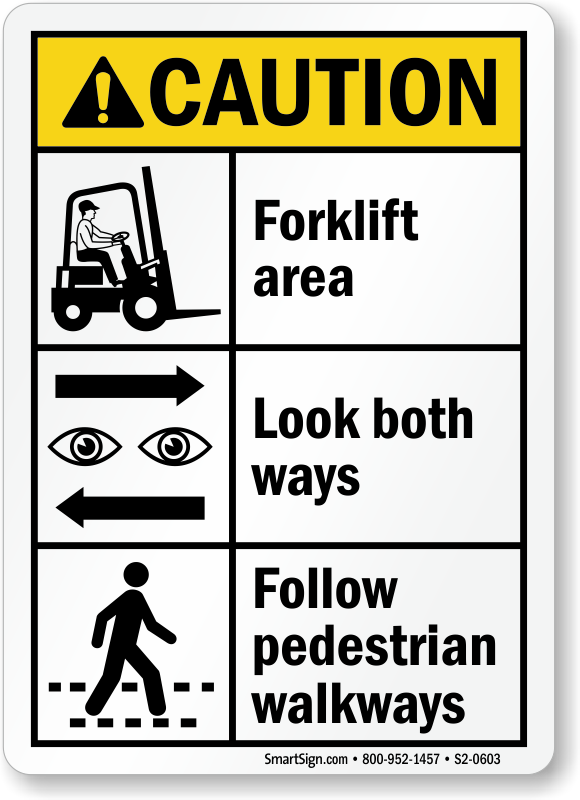

The Facts!

Did you know that an average sized forklift weighs as

much as a dump truck?! That’s huge! Can you imagine trying to stop a dump

truck? Due to the weight of forklifts and the weight of the materials they

carry it takes them longer to stop than a regular vehicle. Trying to stop a

forklift in an emergency can be difficult and coming to too quick of a stop can

cause forklifts to tip over. This is something that is important for forklift operators

and pedestrians to be aware of. One thing that can reduce the likelihood of an operators

need to come to an emergency stop is the use of speed limits in warehouses. There

are times when emergency stops are inevitable; however, forklifts do come

equipped with a wonderful safety feature that is often times underutilized, the

horn. Using the horn when you are backing up, entering isle ways, or around pedestrians

is a great way to prevent emergency stops as well as accidents!

…So

Call

For any questions or concerns regarding your material

handling needs give us a call at (513) 842-2012 or e-mail us at omega.rockett@yahoo.com! And don’t

forget to keep an eye out for our next blog!