When

most of us refer to forks we’re talking about the kitchen utensil. However,

there are a select few of us who are referring to forklift forks. In the

industry, you’re always hearing about the potential dangers of forks, or about some of the hysteria they’ve caused. What people don’t talk about enough is how

forklift forks vary in size, shape, capacity, and the fact that they need to be

maintained. Although this isn’t as fun as talking about someone spearing open a

huge drum of bacon, or a water pipe, it is important and needs to be touched

upon.

How

Much Do You Know?

1. Palleted

and non-palleted items require different kinds of forks.

a. True

b. False

2. The

best way to ensure you are changing your forklift’s forks properly is by

referring to…

a. Wikipedia

b. The

manual

c. By

watching someone else do it

3. When

parking a forklift, it is always a good idea to make sure the forks are…

a. Close

to the ground and pointed in a downward direction

b. Lifted

a couple feet off the ground, but pointed downward

c. Close

to the ground and pointed upwards

4. When

a forklift’s fork is damaged it is important to check the fork mount for damage

as well.

a. True

b. False

Get

This…

There are three main mount types for forklift forks.

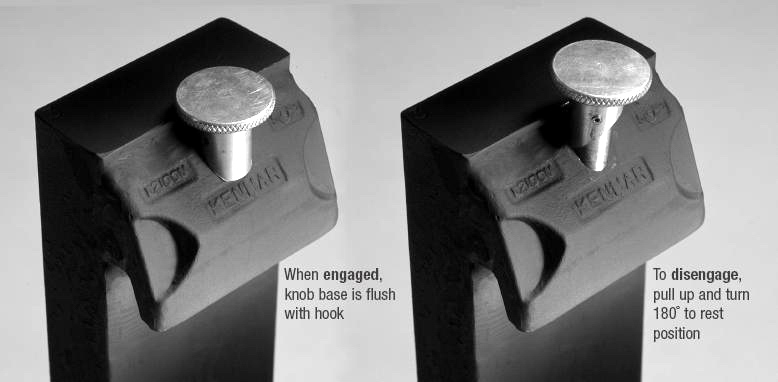

Standard Hook: Top

and Bottom locking mechanism.

Pin:

Rod, shaft, or pin that fits into the “eye” of the fork.

Non-Standard

Hook: Combination of the standard hook and pin mounts.

Can

You Answer This Question???

All forklift forks are created to lift the same weight

capacity?

a. True

b. False

If you chose A then you better do a little more

research! Not all forks are created equal. Different types of forklifts require

different types of forks; all of which perform different tasks, and have

different weight limits associated with them. Often times the types of forks

and the weight limit of your forklift’s forks are listed in the truck’s manual.

Get

The Facts!

Having bent or damaged forks on your forklift can

cause a lot of issues. First of all using forks that are not in good shape can

create a major safety issue. Bent and damaged forks can also cause the operator to

puncture packaging, and can make it harder for them to lift materials. There are

many people who are not comfortable or qualified to change their truck’s forks,

but for a better understanding here is a quick overview!

Step 1: It might seem

fairly basic, but is arguably the most important part of this process… check

out the manual! This ensures that you know exactly what kind of forklift you

have, what type of mount you are working with, and the types of forks you need.

Step 2: Make sure you

have plenty of space!

Step 3: Turn off your

forklift, unless otherwise noted in the manual.

Step 4: Study the forks

and the mount. It isn’t a bad idea to make a sketch of the placement of your

mount, forks, and screws to aide in putting them back together.

Step 5: Now it’s time to

release the forks. Some newer forklifts have quick change forks, while older

models do not. For older forklifts you will first have to release the top

mechanism, once the forks are rested on the ground, the bottom mechanism can be

released. For forklifts with a pin lock release the mount, and remove the pin

from the “eye” of the fork. MAKE SURE OLD

FORKS ARE LABELLED AND DISPOSED OF PROPERLY!

Step 6: Place your new

forks in front of the forklift, reverse your actions from the previous step,

and make sure that everything is secured tightly!

|

…So

Call

If you’re one of those people who isn’t quite sure

about changing forks on your own feel free to shoot us an E-mail at omega.rockett@yahoo.com, or give us a

call at (513) 842-2012.

Your blog is very informative. Eating mindfully has been very hard for people these days. It's all because of their busy schedules, work or lack of focus on themselves. As a student I must admit that I have not been eating mindfully but because of this I will start now. It could help me enjoy my food and time alone. Eating mindfully may help me be aware of healthy food and appreciating food.รถยกรับจ้าง

ReplyDelete