Working

in warehouses and with heavy machinery doesn’t scream “Save the Environment!”

But did you know that there are multiple ways in which you can make working in your

warehouse a little greener?

How

Much Do You Know?

1. Are

pallets recyclable?

a. Yes

b. No

2. One

way to reduce waste in the warehouse is by using __________ packaging.

a. Biodegradable

b. Plastic

c. Cardboard

3. Waste

from packaging can be reduced greatly by recycling and reusing such materials.

a. True

b. False

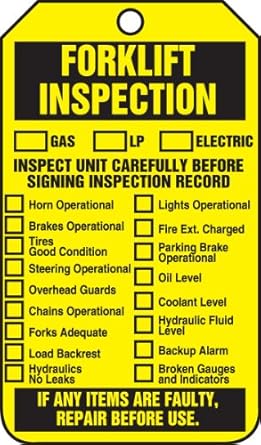

4. Which

forklift fuel type is better for the environment?

a. LP

b. Electric

c. Either,

they have the same overall impact

5. Both electric and LPG forklifts rely on renewable resources to run properly.

a. True

b. False

Get

This…

LPG and electric forklifts are both incredibly common

but utilize two different sources of fuel. LPG forklifts run off a liquid

propane, while electric forklifts are battery powered. Both types of forklifts

have their advantages and disadvantages. However, the question remains, is one

type of forklift more environmentally friendly than the other? For the most

part electric forklifts are more environmentally friendly. They eliminate the

use of propane fuel (a non-renewable resource), and the disposal of many of the

fluids used in LPG trucks. Electric forklifts also eliminate tailpipe

emissions. Not only is this elimination of emissions better for the

environment, but also for your employees because it reduces the amount of

chemicals and smoke they are inhaling. After hearing all of this you may

wonder where the debate lies. It’s clear that electric forklifts utilize

batteries to run, very large batteries. There is still some discrepancy on how

these batteries should be disposed of and/or recycled. Although, overall it has been concluded that electric forklifts have less negative impact on our surrounding environment.

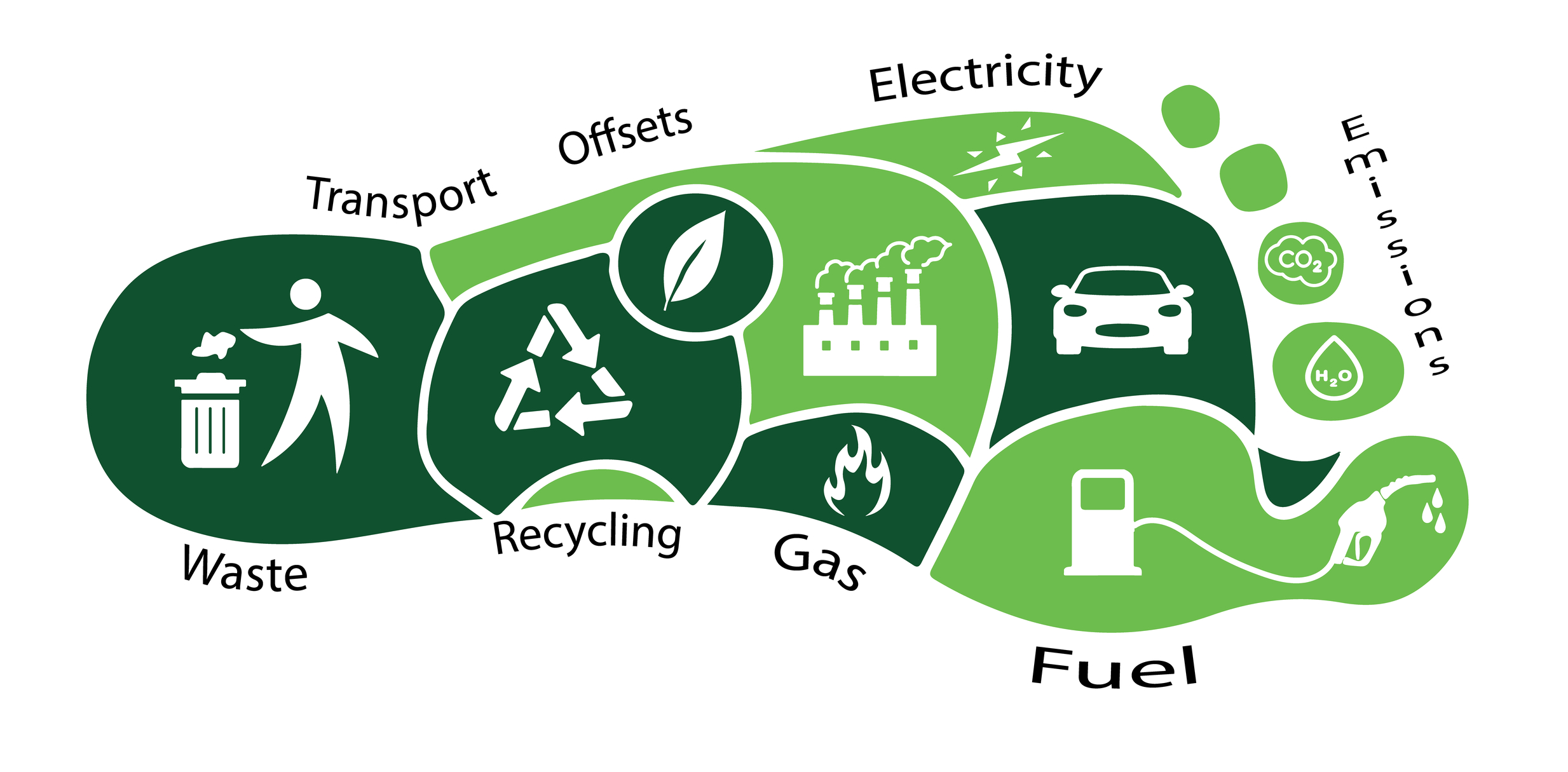

Can

You Answer This Question???

What is a carbon footprint?

a. Measured

output units of CO2 and methane for an individual, business, or product.

b. Measured

output units of CO2 for an individual, business, or product.

c. Measured

output units of CO2, water vapor, and methane for an individual, business, or

product.

The phrase Carbon

Footprint is thrown around quite often, but what exactly is a carbon

footprint? If you chose A as your answer then you are correct! CO2 and Methane

are the two largest greenhouse gas contributors, making it important for us to

monitor the amounts of these gases we are releasing into the environment. This

calculation can be made for an individual, a business, or a product. Reducing

your carbon footprint even just a little bit can make a huge difference to our

environment! Calculate your personal carbon footprint and your company’s carbon

footprint here: https://www3.epa.gov/carbon-footprint-calculator/ !

Get

The Facts!

Time to talk about pallets! Pallets are often used in

warehouses around the world. There are many different shapes, sizes,

and materials used to make pallets. Fortunately, many pallets are made from

wood, which is a recyclable material. In addition to being able to recycle

pallets there are a lot of companies that will pay you for your pallets. If you're opposed to selling or recycling your pallets you can also up-cycle them! Which basically

means that you are using pallets to make other things, for example, a planter.

To buy, sell, and find free pallets check out this website: https://repalletize.com/content/Cincinnati-free-pallets

. For up-cycling ideas look here: https://phsinverter.com/10-ways-recycle-wood-pallets-house/

, https://phsinverter.com/top-uses-for-old-wood-pallets/

…So

Call

There are thousands of ways to Reduce, Reuse, and

Recycle at work, whether it be in the office or the warehouse! If you have

large items that you need removed and recycled check out these sites: https://www.junk-king.com/services/items-we-take/

, http://www.ecycleenvironmental.com/scrap-recycling/warehouse-recycling

For any other material handling needs give us a call

at (513) 842-2012. Thanks for checking out our blog!

Multiple Choice Answers: 1/A, 2/A, but cardboard is recyclable!, 3/A, 4/B, 5/B