How

many of us actually do a pre-use forklift inspection? I’m sure less of us than

we’d like to admit. However, these checks are incredibly important to protect

your business and your operators!

How

Much Do You Know?

a. Yes

b. No

2 . How

often should a pre-use forklift examination occur?

a. Every

shift change

b. Daily

c. Before

use whenever changing operators

3 . What

must you check when going through your pre-use checklist?

a. Mast,

tires, lights

b. Tires,

lights, brakes

c. There

are no OSHA requirements on what specifically needs to be checked

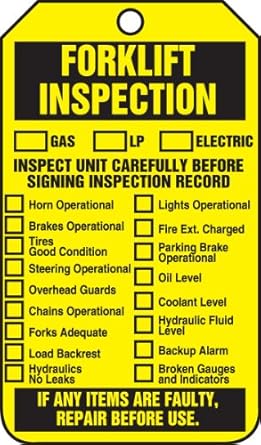

A visual inspection of your forklift is to be done at

least daily before forklifts are put to use. A visual inspection should

include:

· Fluid

levels including: oil, water, and hydraulic fluid

· Tire

condition and pressure

· Leaks,

cracks, or any other noticeable defects in mast chains, ect.

· Load

backrest extension

· Fork

condition

· Nameplates

and safety decals

· Operator

compartment

After doing a physical inspection of your forklift it

is just as important if not more important to do an operation check. Things you

should look for during the operational check include:

· Brakes

· Steering

· Drive

control, tilt control, hoist and lowering control, and attachment control

· Horn

· Lights

· Back

up alarm

· Hour

meter

Can

You Answer This Question???

Is there an OSHA regulation for maintaining checklist

documents?

A. Yes

B. No

Although OSHA requires you to perform a pre-use check they do not currently require companies to create and keep paperwork on

pre-use inspections. With that said it is a good idea to keep pre-use documentation in case an accident is to occur. It is recommended that any

paperwork created for forklift checks is kept for at least a month.

Get

The Facts!

It can be tough to tell when your forks and tires

actually need to be replaced. So, check out these videos for a more in depth

look!

…So

Call

If you’re unsure how to perform a pre-use check on

your forklift give us a call! We’ll have one of our knowledgeable team members

come out and walk you through it. You can reach Omega Material Handling at (513)

842-2012, or by sending an e-mail to omega.rockett@yahoo.com.

Answers:

1/A

2/B 3/C 4/B